Compressed air quality in production and manufacturing

GENERAL

Compressed air plays an important role in almost every production operation. Modern production machines use compressed air to drive tool spindles, move the workpiece and clean finished parts. Although mechanically processed workpieces and machine tools weighing several tons are not as sensitive to poor compressed air quality as, for example, food or pharmaceutical products, the influence of particle contamination, high dew points and residual oil levels on the manufacturing industry should not be underestimated.

Quality requirements in the manufacturing industry

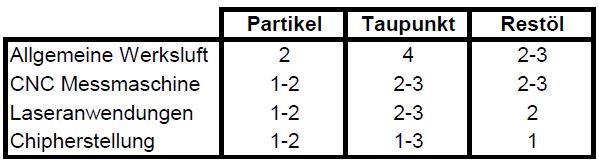

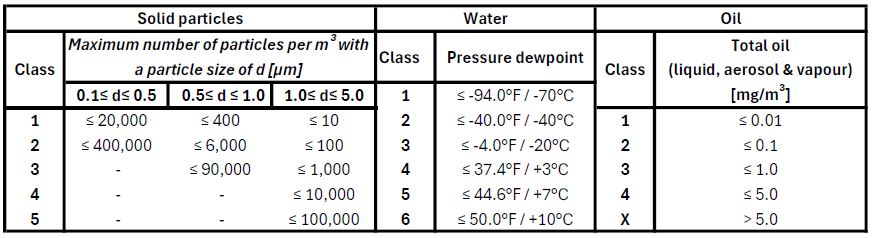

The three most relevant contaminants in compressed air are particles, moisture and oil. DIN EN ISO 8573-1:2010, the relevant standard for the objective classification of compressed air quality, is also based on these three categories. The quality classes required for a given machine are normally specified by the machine manufacturer in its data sheet. As the range of applications for compressed air in mechanical manufacturing and production is enormous, there are no generally applicable standards or standardized specifications in this area. The following graphic provides a rough overview of frequently encountered recommendations and best practices.

The different quality classes can be achieved by combining different treatment units tailored to the specific requirements.

Druckluftqualität gemäß ISO 8573-1:2010

Problems due to high levels of compressed air contamination

Particles:

Among other things, a high particle load can lead to sensitive surfaces being damaged. These surfaces can be on the actual product, but can also affect mating surfaces in tool heads, bearings or laser units. Particles in a compressed air flow are accelerated enormously and hit components or tools at high speeds. Together with a high oil load, an abrasive paste can form, which leads to increased wear in bearing points or on other moving parts, for example. This results in shorter service lives for critical tools, negatively affected product quality and production downtime.

Humidity:

The main problem of excessive moisture in compressed air is corrosion in pipelines and tools. This corrosion can lead to production downtime due to defects, or inefficiencies and even machine failure due to pressure loss caused by leaks in pipelines. Water and oil do not mix, so condensed water droplets can disrupt lubricating films in machines, which can also lead to increased wear.

Oil:

Excessive oil contamination in the compressed air can disrupt sensitive devices or render them unusable. At high temperatures due to friction or other influencing factors (injection molding machines, fast-running tools, etc.), residual oil components in the compressed air may resinify. This can hinder movements and narrow pipe diameters. This leads to reduced efficiency and productivity or even to production downtime and machine failure.

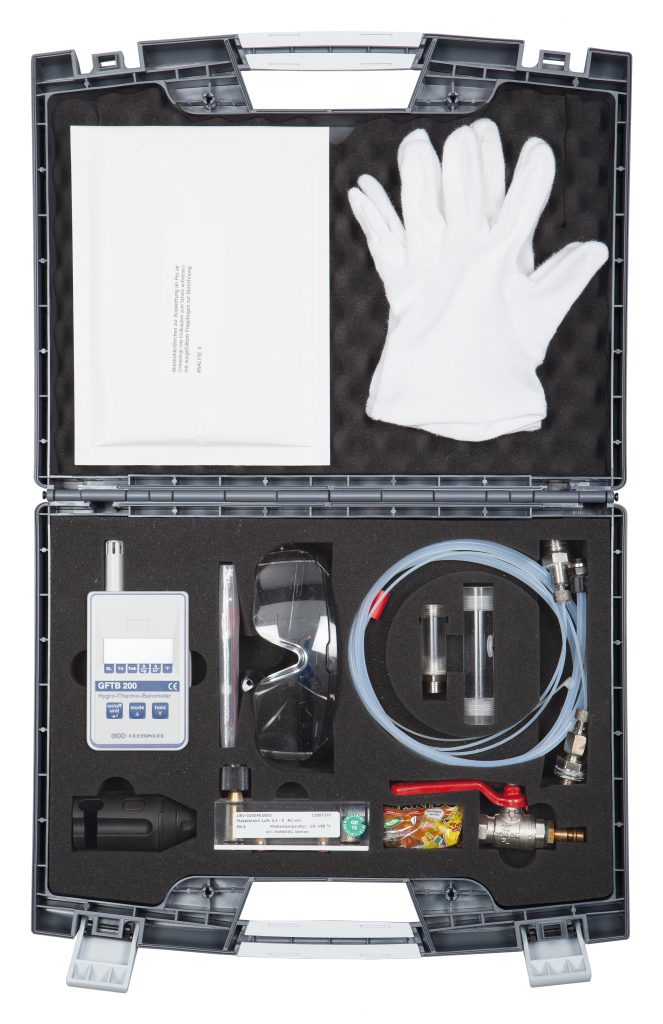

Options for determining the compressed air quality

Pro Air offers various services and products for determining and checking compressed air quality and thus ensuring the productivity of your production.

time-limited analysis:

- Quality analysis according to ISO 8573-1

- Residual oil determination

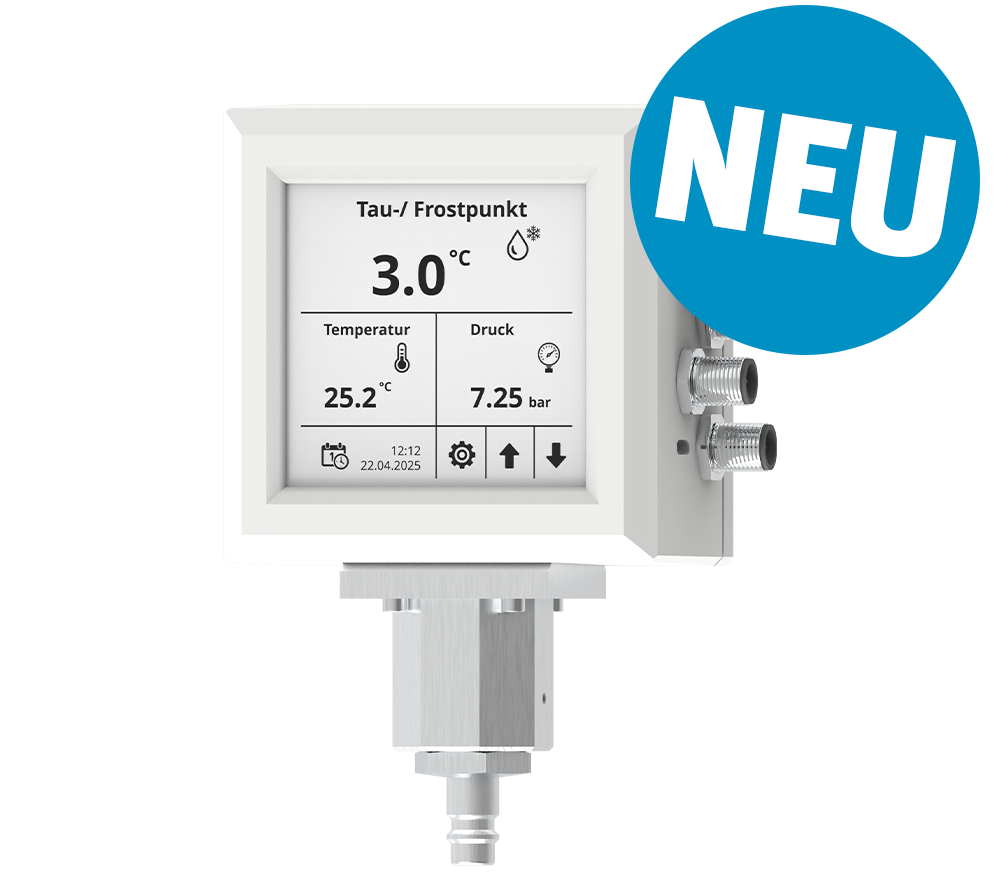

continuous monitoring:

- TPK25

- oilguard

- particleguard

How can we help you?

We look forward to your call or email and are happy to assist you with advice and support!

Mo - Fr from 7 till 17 Uhr