Compressed air quality in the food industry

GENERAL

Compressed air, or pneumatics, plays a major role in many areas of the food industry. It is used for transporting ingredients, processing doughs and drinks and packaging finished products. Even if the compressed air does not come into direct contact with the product, it is often used to operate machines and systems, to transport containers and for other ancillary activities.

Compressed air systems can usually be divided into 3 broad areas: Generation, treatment and distribution. In many companies, the generation (compressor or compactor) and treatment (filter and dryer) are located in the so-called compressor room. The distribution extends over the entire production area and is usually realized by widely branched pipe networks.

POSSIBLE RISKS FROM COMPRESSED AIR

Due to the direct or indirect contact of compressed air with the final product, compressed air is considered a critical control point in HACCP where product safety can be compromised.

As the compressed air passes through many different units and travels long distances before it reaches the point of use, there are many potential sources of contamination: In the compressor due to mechanical abrasion, at leaking valves or screw connections, in filters at irregularly maintained filter elements…

QUANTIFICATION OF COMPRESSED AIR QUALITY

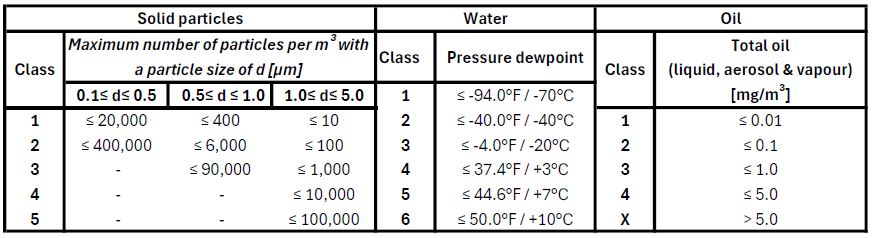

ISO 8573 was created to make the compressed air quality in the network objectively measurable and controllable. This standard lists the most important contaminants in compressed air systems and divides them into quality classes: Particles, water, oil.

Druckluftqualität gemäß ISO 8573-1:2010

In addition, the sub-standard ISO 8573-7:2003 defines a test method for determining viable microbiological contamination. This makes it possible to determine or rule out the presence of bacteria and fungi in the air.

MAINTAINING THE COMPRESSED AIR QUALITY

The quality of compressed air in food production must be ensured by several measures in accordance with GMP:

1. selection of appropriate systems and components to achieve the quality requirements

2. appropriate upkeep (maintenance) and review of the system and the associated quality requirements

3. documentation of processes, maintenance, calibrations and test procedures for compliance with regulatory requirements

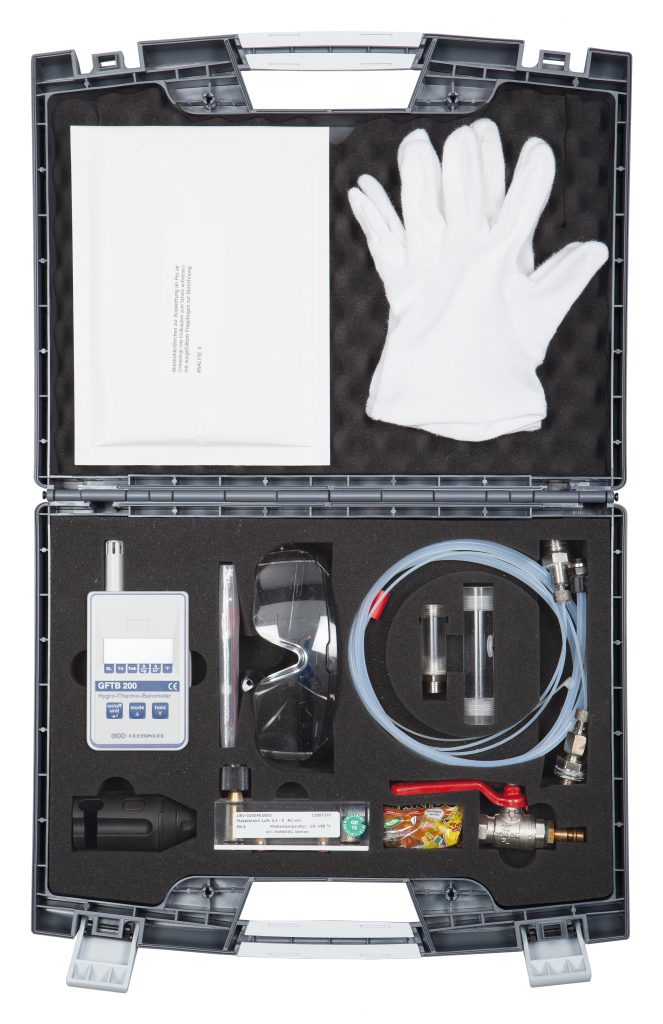

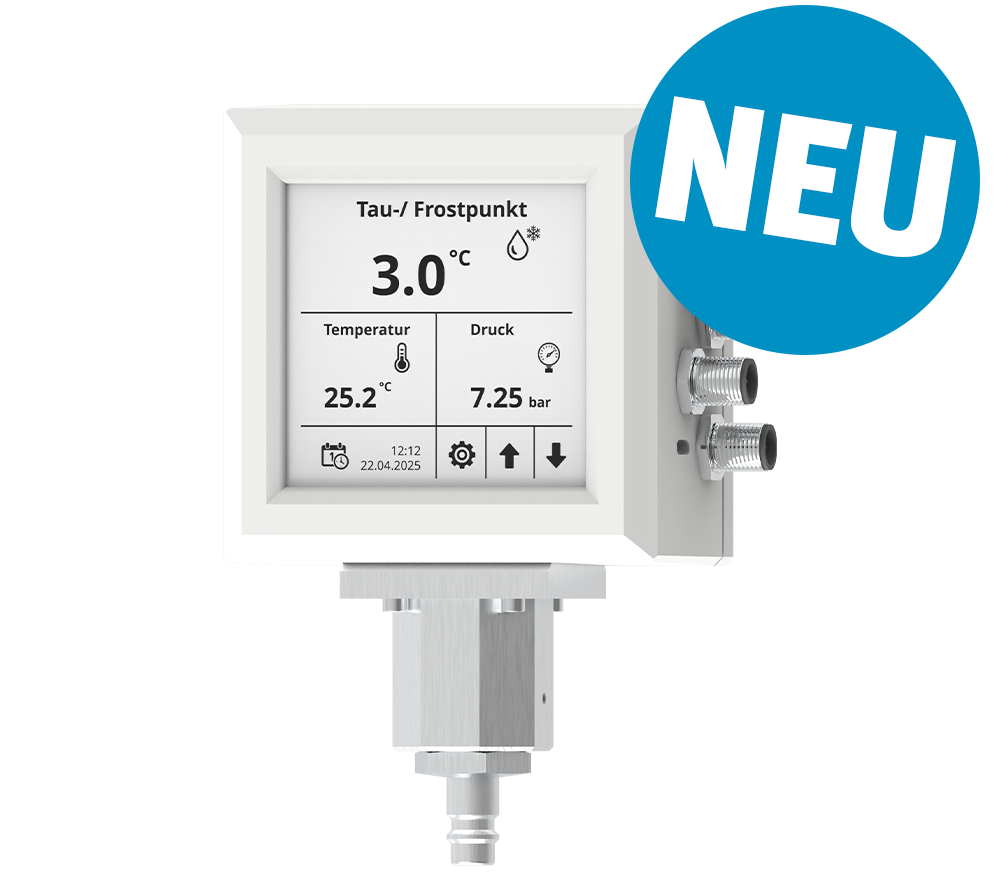

Pro Air’s measuring instruments and analysis services can support users, quality assurance officers and compressed air specialists.

How can we help you?

We look forward to your call or email and are happy to assist you with advice and support!

Mo - Fr from 7 till 17 Uhr